Our Products

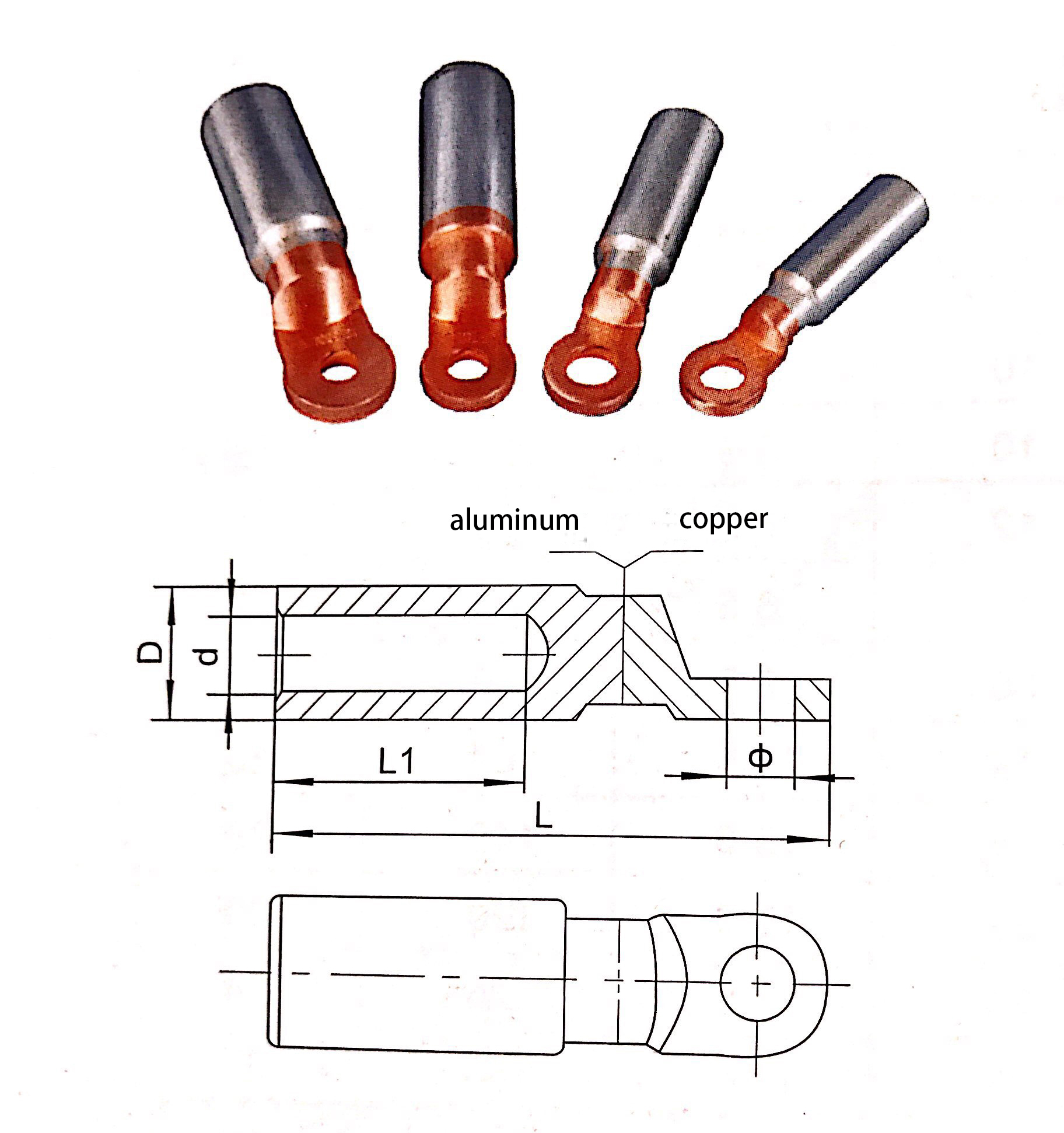

2019 High quality Cable Termination Kits - Bimetallic Lug Copper Wire Terminal(DTL) – Wangyuang

2019 High quality Cable Termination Kits - Bimetallic Lug Copper Wire Terminal(DTL) – Wangyuang Detail:

| PRO.NO | Dimensions(mm) | ||||

| Φ | D | d | L | L1 | |

| DTL-2-16 | 8.5 | 16 | 5.5 | 90 | 42 |

| DTL-2-25 | 8.5 | 16 | 6.5 | 90 | 42 |

| DTL-2-35 | 8.5 | 16 | 8.5 | 90 | 42 |

| DTL-2-50 | 12.8 | 20 | 9 | 90 | 43 |

| DTL-2-70 | 12.8 | 20 | 11 | 90 | 43 |

| DTL-2-95 | 12.8 | 20 | 12.5 | 90 | 43 |

| DTL-2-120 | 12.8 | 25 | 13.7 | 118 | 60 |

| DTL-2-150 | 12.8 | 25 | 15.5 | 118 | 60 |

| DTL-2-185 | 12.8 | 32 | 17 | 120 | 60 |

| DTL-2-240 | 12.8 | 32 | 19.5 | 120 | 60 |

| DTL-2-300 | 12.8 | 34 | 22.5 | 130 | 62 |

| DTL-2-400 | 12.8 | 41 | 26.5 | 145 | 70 |

| DTL-2-500 | Square head | 47 | 29.5 | 200 | 90 |

| DTL-2-630 | Square head | 47 | 34 | 200 | 90 |

|

The Guide for Bimetallic Lug Copper Wire Terminal Chapter 1 – Types Of Terminal Connector

|

Terminal connectors are used to connect tap conductor to power equipments (transformer,circuit breaker ,disconnet switch.etc)or to wall bushing of substation.Aluminum connectors are also used to connect the tap conductor of T-connector. The connectors include conpressive-type and bolted,both types have angle of O°、30° and90° with the direction of tap conductor.

DTL series AICu connection terminal is suitable for transition joint of distribution device Aluminium core cable and electric equipment. DL Aluminium is used for aluminum terminal linking of Aluminium core cable and electric equipment.DT copper terminal is used for copper terminal electric equipment.DT copper terminal is used for copper terminal linking of copper core cable and electric equipment,The products adopt friction welding workmanship,Our company supplies Cu-AI terminal and wire clamp made explosive wedling technique.The products have features as high welding strength, excellent electric property, resistance to galvanic corrosion, long service life, never fracture,high safety, etc.

Chapter 3– Installation steps Of Bimetallic Lug

1. Open the package, check whether the product model is consistent with the copper and aluminum wires installed, and then install after confirming the correct selection;

2. Installation steps:

(1) peel off the insulation layer at the bonding site of the aluminum conductor, and the stripping length is greater than the effective hole depth of the corresponding terminal model, which is about 1 ~ 2mm;

(2). Try to avoid damaging the conductor when stripping the conductor insulation layer;

(3) press the stripping part of the aluminum wire into the root of the inner hole of the terminal along the direction of the stranded wire;

(4) at the compression joint, the forming edge of the confining pressure or the center line of the crater shall be on the same plane or straight line respectively

(5) for each die pressing, the die should stay for 10~ 15s after it is closed in place, so that the metal in the die pressing position will be deformed

To achieve basic stability, to eliminate the pressure;

(6) the operation method and matters needing attention of the pressure clamp should be pressed according to the manufacturer’s manual;

(7) after pressing, the appearance quality of the joint shall meet the following requirements:

A. after confining pressure, the pressing surface should be smooth without cracks or burrs, and all edges should have no tips;

B. After the pit is pressed, the depth of the compaction shall be the same as the height of the press-in part due to the male die, and the pit bottom shall be flat and non-destructive;

(8) after pressing, connect the eye of the terminal board with the electrical equipment firmly with bolts.

Product detail pictures:

Related Product Guide:

High quality Very first,and Consumer Supreme is our guideline to offer the most beneficial service to our consumers.At present, we're attempting our greatest to be among the top exporters in our area to fulfill buyers far more need to have for 2019 High quality Cable Termination Kits - Bimetallic Lug Copper Wire Terminal(DTL) – Wangyuang , The product will supply to all over the world, such as: Lithuania, Nepal, Morocco, The company has perfect management system and after-sales service system. We devote ourselves to building a pioneer in the filter industry. Our factory is willing to cooperate with different customers domestic and overseas to gain better and better future.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed